BoxOnPallet features(*)System requirements

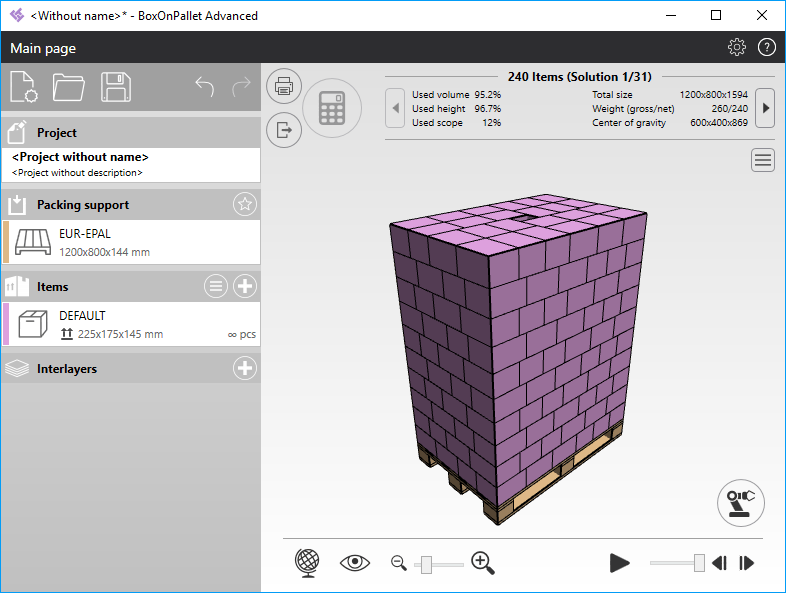

XMHE® heuristic search engine

The powerful XMHE® heuristic engine has been developed using the most advanced processing technologies and allows you to obtain optimal solutions in a few seconds. The load solutions are then sorted according to the efficiency criterion and displayed in 3D format for a simpler and more immediate interpretation by the user.

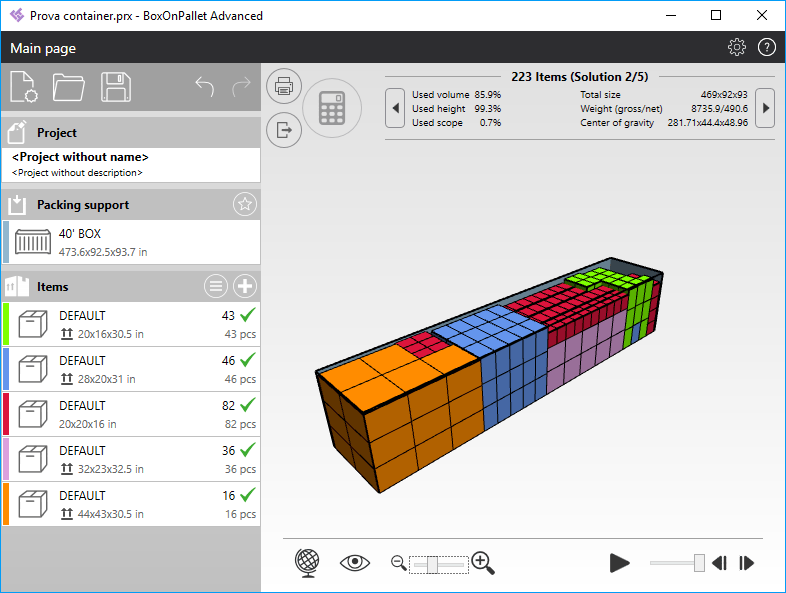

Container Load Optimization

In a similar way looking for the optimal arrangement of articles on a pallet, BoxOnPallet allows to determine the best loading strategies of objects within containers and trucks. The optimisation of the available load volume results in a significant reduction in transport costs.

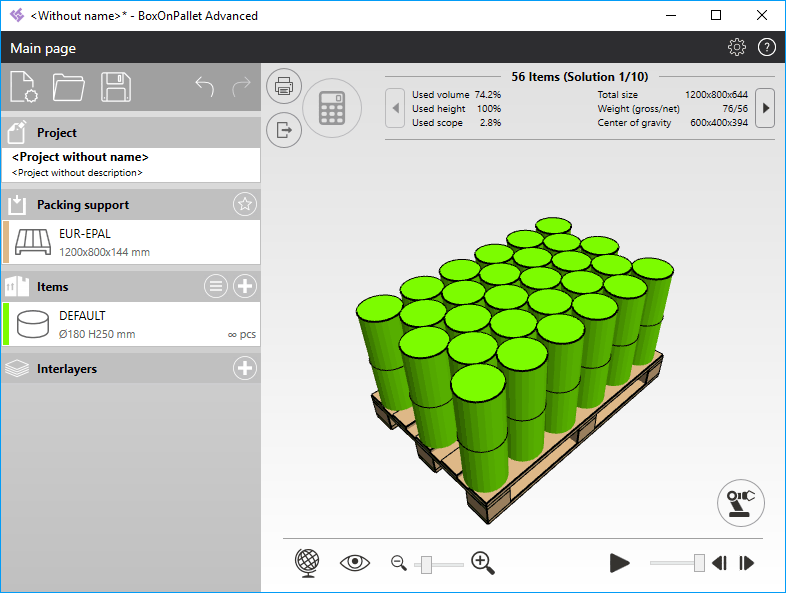

Search for solutions for boxes and cylinders

BoxOnPallet can be used indifferently for the optimization of the load of objects with rectangular base (boxes) or with circular base (cylinders, bottles). The search algorithm automatically adapts to the different product types in order to always provide optimal solutions.

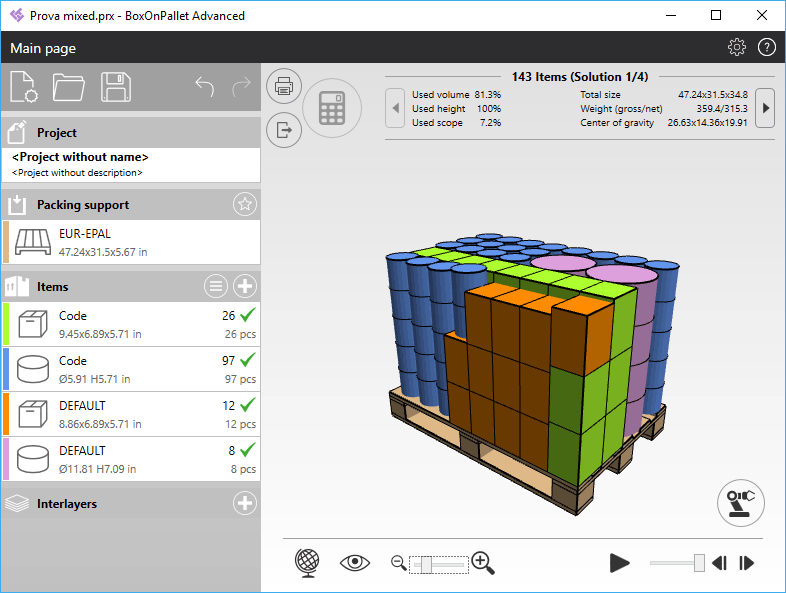

Mixed Solutions

BoxOnPallet has flexible and efficient calculation algorithms that allow you to quickly obtain loading planes where you need to insert different shape and size objects. If so, simply fill in the list of articles, define the container and press the Calculate button: in a few moments will be displayed highly optimized solutions that, in fact, would be impossible to obtain in reasonable time with "paper and pen" approaches.

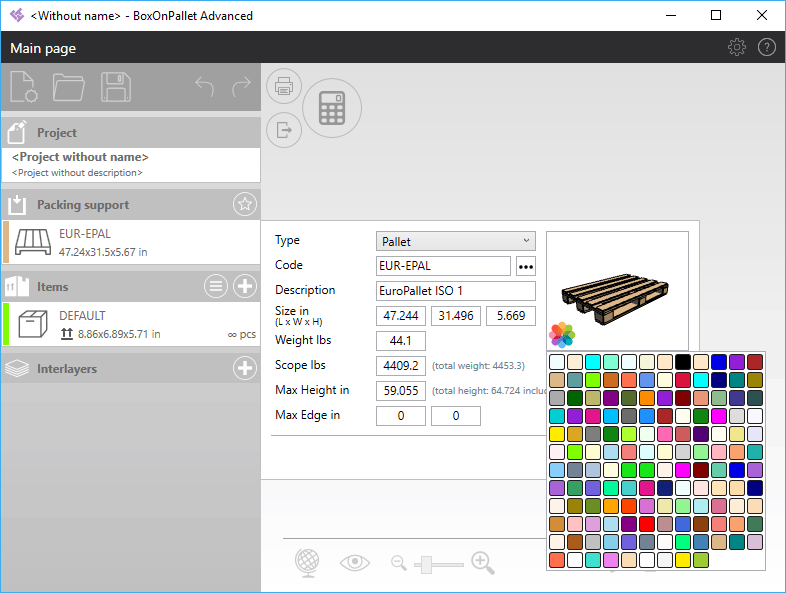

Customization

All elements that are part of the project (boxes, cylinders, interlayers, pallets, containers, etc.) can be freely defined and customized according to your needs. Each object has specific attributes such as: name, description, size, weight, color, position of labels, etc. For loading units (pallets and containers) it's also possible to indicate characteristics such as the maximum load height, the flow rate, the maximum permissible overflow, etc.

Additional features

- Recursive solutions. In the case where the selected load unit cannot contain all the items inserted in the project, BoxOnPallet can automatically create a new project with the items left unused.

- Auto Spacing. If the option is enabled, in some types of solution, the objects will be appropriately spaced in order to occupy the entire surface of the pallet or container.

- Crossed layers. The function allows to increase the stability of the load by repositioning any layers according to a "crossed" pattern. The optimization algorithm automatically evaluates the possible strategies (horizontal mirroring, vertical mirroring, rotation) in order to maximise the contact surface and, consequently, the stability of the solution.

- Label arrangement outward. BoxOnPallet allows to optimize the arrangement of the boxes in order to guarantee (consistent with the constraints of the load schema) the visibility of the labels of the boxes on the outer perimeter.

- Insertion of separators (interlayers) between any layers.

- Interactive modification of the 3D view of the pallet or container for easier analysis of the proposed solution.

- Simulation of the load sequence. BoxOnPallet provides the ability to display, by animation, the entire load sequence of objects.

- Print and export to the PNG, JPG, and BMP formats of the Load Plan summary sheet.

- Importing the list of items to be inserted into the load plan.

- Export in the XML and CSV formats of the load sequence data (type of elements, position, rotation, etc.).

- Sending data to X-PAL® palletizer produced by X Machine.

(*) The features described refer to the "Advanced" version of BoxOnPallet. See the Download section for comparison of features offered by the different versions of BoxOnPallet.